Shale Shaker Screens

Shale Shaker Screens

VPrime Energy Solutions specializes in the design and manufacturing of replacement shale shaker screens that conform to API RP 13C standards.

We offer a comprehensive range of standard and custom replacement screens, engineered for high performance, exceptional durability, and seamless compatibility with all major OEM brands in the Oil &Gas industry.

Disclaimer:

BRANDT, COBRA, KING COBRA, VENOM, and VSM 300 are trademarks or registered trademarks owned by National Oilwell Varco.

M-I SWACO, MONGOOSE, and MEERKAT are trademarks or registered trademarks of M-I L.L.C.

Derrick, FLC500, and FCL2000 are trademarks or registered trademarks of Derrick Corporation.

Continental Wire Cloth does not produce screens for NOV Brandt® or Derrick®. CWC offers compatible replacement screens that serve as alternative solutions for solids control requirements.

| API RP 13C(ISO 13501) | |

| D100 Separation(Microns) | API Screen Number |

| >780.0 to 925.0 | API 20 |

| >655.0 to 780.0 | API 25 |

| >550.0 to 655.0 | API 30 |

| >462.5 to 550.0 | API 35 |

| >390.0 to 462.5 | API 40 |

| >327.5 to 390.0 | API 45 |

| >275.0 to 327.5 | API 50 |

| >231.0 to 275.0 | API 60 |

| >196.0 to 231.0 | API 70 |

| >165.0 to 196.0 | API 80 |

| >137.5 to 165.0 | API 100 |

| >116.5 to 137.5 | API 120 |

| > 98.0 to 116.5 | API 140 |

| > 82.5 to 98.0 | API 170 |

| > 69.0 to 82.5 | API 200 |

| > 58.0 to 69.0 | API 230 |

| > 49.0 to 58.0 | API 270 |

| > 41.5 to 49.0 | API 325 |

KEY FEATURES

- Innovation Design

- Enhanced processing rates

- Advanced Composite Construction

- Lightweight design

- Improved separation efficiency

- High Quality Metal construction

- Corrosion-Resistant MOC

EXCLUSIVE BENEFITS

- Increased Screen longevity

- Maximizing fluid recovery and Minimizing waste volumes

- Reducing the need for dumping and dilution of Drilling Fluids

- High Quality Stainless Steel Wire mesh for longer screen life

- Frame type Replacement Screens

- Flat / Plate type Replacement Screens

- Customized Size Screens

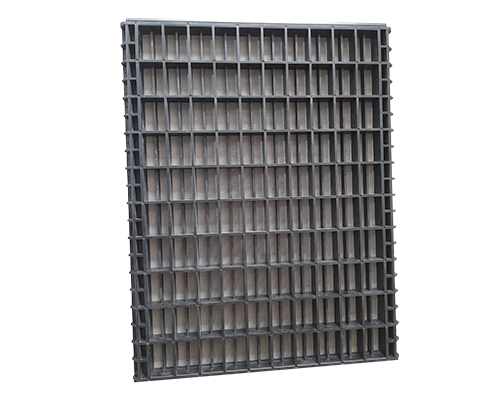

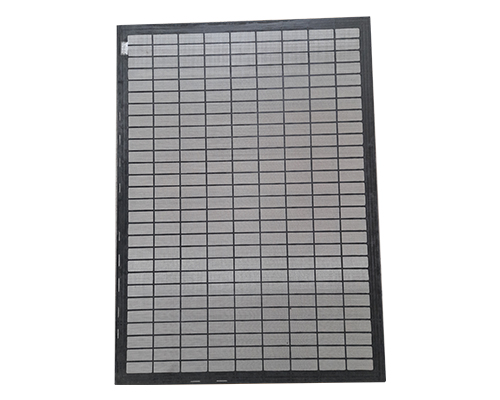

Hook Strip Flat Screens

| OEM Replacement Screens | |

| Model Code | Size |

| VP-D500-FLT | 1050 x 697 mm |

| VP-D2000-FLT | 1050 x 697 mm |

| VP-DFE-FLT | 1220 x 720 mm |

| VP-LCM-FLT | 915 x 1150mm |

| VP-MFF695-FLT | 1050 x 695 mm |

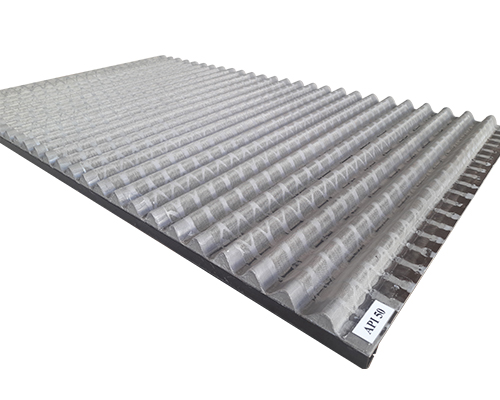

Wave Screens

| OEM Replacement Screens | |

| Model Code | Size |

| VP-D500-WAV | 1050 x 697 mm |

| VP-D2000-WAV | 1050 x 697 mm |

| VP-D626-WAV | 710 x 626 mm |

| VP-LCM-FLT | 915 x 1150mm |

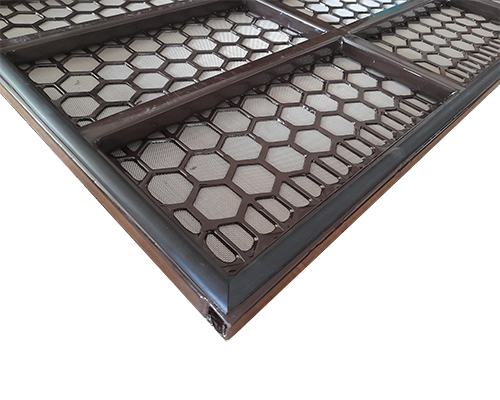

Metal Frame Screens

| OEM Replacement Screens | |

| Model Code | Size |

| VP-MON-MFS | 1165 x 585 mm |

| VP-COB-MFS | 1250 x 635 mm |

| VP-VOR-MFS | 1173 x 610 mm |

| VP-GNS-MFS | 1250 x 700 mm |

| VP-V300P-MFS | 902 x 686 mm |

| VP-V300S-MFS | 940 x 676 mm |

| VP-MD3-MFS | 655 x 622 mm |

| VP-BEM-MFS | 910 x 700 mm |

| We also manufacture Custom Size Screens | |

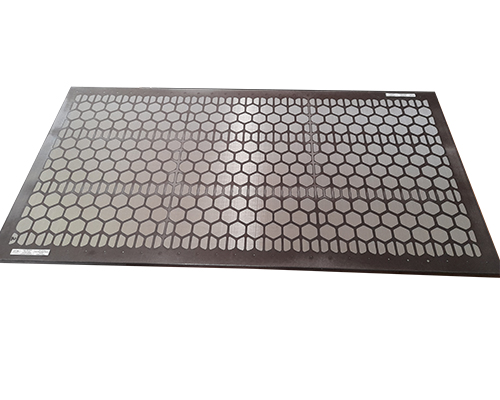

Composite Screens

| OEM Replacement Screens | |

| Model Code | Size |

| VP-MON-COM | 1165 x 585 mm |

| VP-COB- COM | 1250 x 635 mm |

| VP-V300P- COM | 902 x 686 mm |

| VP-V300S- COM | 940 x 676 mm |

| VP-MD3- COM | 655 x 622 mm |